Electrical Infrared Inspections

Building Electrical Equipment system failures can be costly. Infrared inspections

are performed without any service interruption. They detect faults in their early

cycles, prioritize preventative maintenance, enhance personnel safety, ensure

reliability, and help to avoid unscheduled shutdowns.

Mechanical Infrared Inspections

Building Mechanical HVAC system failures can be costly. Infrared inspections

are performed without any service interruption. They detect faults in their early

cycles, prioritize preventative maintenance, enhance personnel safety, ensure

reliability, and help to avoid unscheduled shutdowns.

Snow melting & Heat trace Infrared Inspections

Building Snow Melting Heat-Trace failures can be costly. Infrared inspections

are performed without any service interruption. They detect faults in their early

cycles, prioritize preventative maintenance, enhance personnel safety, ensure

reliability, and help to avoid unscheduled shutdowns.

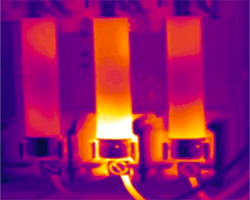

Electrical Distribution System Infrared Inspection

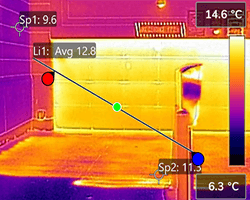

Mechanical HAVC System Infrared Inspection

Snow melting & Heat trace Infrared Inspection

Electrical Equipment Infrared Inspection

- Distribution system equipment

- Transformers, Panel bards

- Switchgears bus-bars

- Transformers, panel boards

- Faulty circuit breaker, fuses

- Loose connections, Imbalanced loads

- Electrical faults or circuit shortage

- Equipment malfunction or degradation

- Excessive current or voltage anomalies

- Motor starter, MCC,s

Mechanical Equipment Infrared Inspection

- Overheating bearings

- Misalignment, Fluid leaks,

- Belt and coupling issues

- Motor winding faults

- Electrical connection problems

- Duct leaks and other issues efficiently.

- Air handling Units (AHU)

- Insulation degradation

- Hot spots, leaks in hydraulic systems

- Chillers, Boilers, Generators, Cooling towers

Snow melting Heat trace Infrared Inspection

- Malfunctioning heating elements.

- Insulation degradation.

- Uneven heat distribution.

- Electrical component failures.

- Wiring issues.

- Heat trace: applications are vital for preventing freezing and maintaining optimal temperatures in various systems, pipes, roofs, and gutters, ensuring functionality and preventing costly damage.